Technical data and information

Ultrasint® AP26 harnesses the properties of Polybutylene terephthalates (PBT); high-strength, electronic insulation, and solvent resistance for Powder Bed Fusion (PBF) technologies. First material with up to 100% reusability rate, which translates into zero waste, a real ally for sustainability. An easy-to-print material with high detail resolution suitable for industrial production. The new Ultrasint® AP26 is a Polybutylene terephthalate (PBT), is a high-strength, thermoplastic material commonly used in traditional injection-molded electronic auto parts due to its electronic insulation and solvent resistance. A material that also meets the need for 3D-printed electric and electronic components. Developed for a wide sinter window, the powder is easy to print, making it suitable for industrial production. As the focus of our society shifts toward our environment, Ultrasint® AP26 also draws high marks for its eco-friendliness having very stable mechanics while using 100% of reused material, resulting in zero powder waste. The new Ultrasint® AP26 is, therefore, an ally for sustainability, offering the sharpest detail quality while assuring the lowest cost.

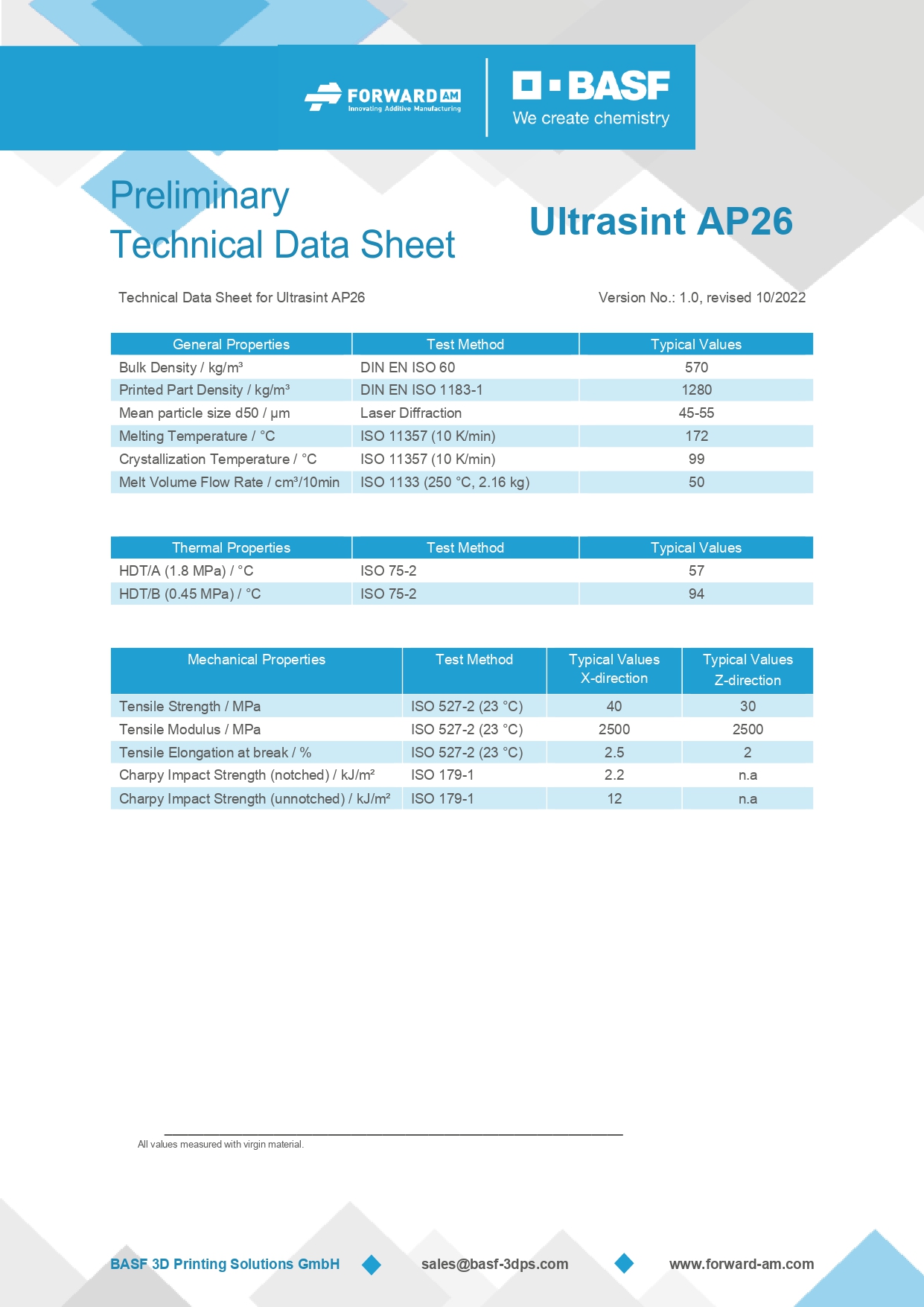

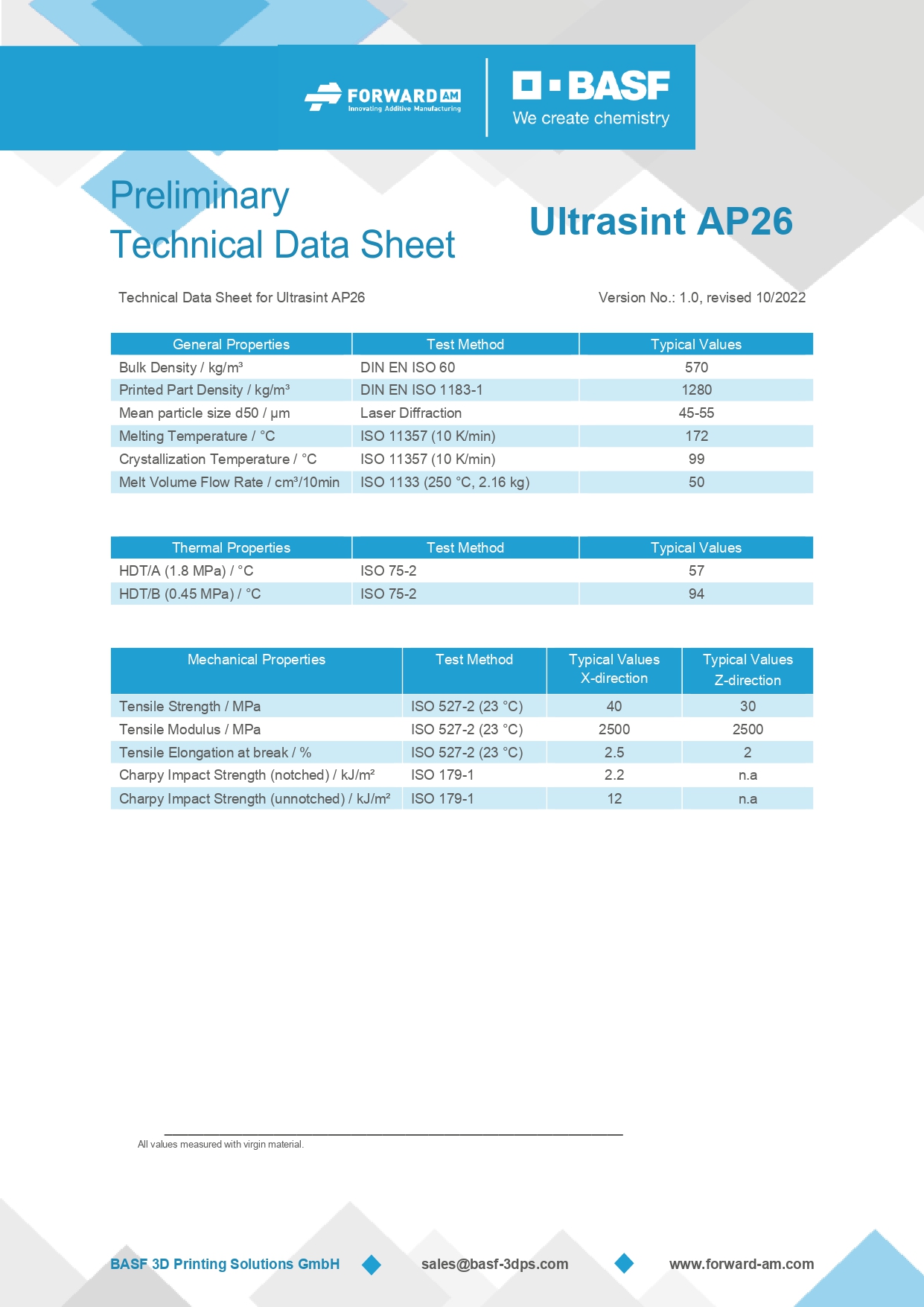

- Tensile strength: 40 MPa

- Young’s modulus: 2500 MPa

- Elongation at break: 2,5 %

- Charpy impact unnotched: 12 kJ/m²

- HDT B (0.45 MPa, dry): 94 °C