|

тел: +359 888 100 273 email: office@grema3d.com |

|

тел: +359 888 100 273 email: office@grema3d.com |

|

Forge1_Technical_Specifications.pdf

S200C_Technical_Specifications.pdf

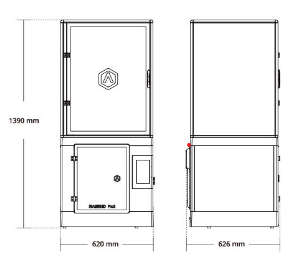

Raise3D has developed a special edition of its slicing program- ideaMaker for Metal – to either slice or import Gcode files to the FFF metal printer – the Forge1 – in order to 3D print models, much like FFF 3D printers that create objects using thermoplastics. In this case, the 3D printer produces what are called green parts. Once these green parts are created, they can be subject to process called debinding, and are placed in another machine, the D200-E. This results in what are called brown parts, and finally the brown parts are quickly sintered in the sintering machine, the S200-C. Out of this last machine come the final metal parts, in a manner similar to the MIM process.