|

тел: +359 888 100 273 email: office@grema3d.com |

|

тел: +359 888 100 273 email: office@grema3d.com |

|

High quality

Printed parts' density > 99.9 %, deviation in parts' mechanical properties < 5 %.

The optimized gas flow design ensures efficient removal of smoke and splashes as well as achievement of uniform and consistent full size printing.

The overall mechanical properties of the printed part remain the same when compared to printing results with other laser machines.

High efficiency

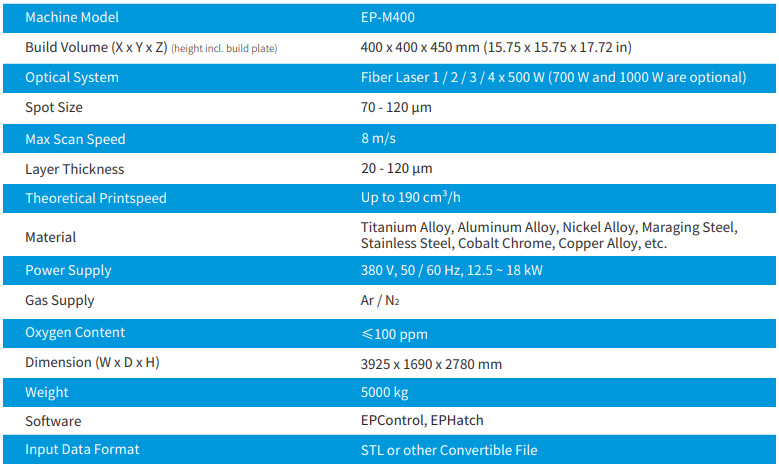

Build volume (X x Y x Z): 400 x 400 x 450 mm (height incl. build plate), build chamber volume > 70 L.

Printing with increased layer thickness can be realized, increasing the production capacity.

With in-house developed processing software (EPHatch), optimized scanning strategies can be achieved with reduced print duration.

Reliable

Excellent core optic components from world-class supplier and mature process controlparameter algorithm provides highest part quality.

High quality uniform part printing due to excellent control over building environment and components.

Tightly sealed build chamber maintains oxygen concentration s100 ppm and a stablepressure during printing.

Sustained monitoring of powder left in feeder and ability to add powder without stopping the machine ensures uninterrupted part printing.

Double protection of chamber door is attained due to dual gas releasing ports on top of printing chamber.

Open system

Open parameters for editing laser power, scan speed, scan direction, up and downfacing surfaces etc.

Open system ensures freedom to choose among wide range of metal powders available in market.

Process software supports SLC and CLI formats.