|

тел: +359 888 100 273 email: office@grema3d.com |

|

тел: +359 888 100 273 email: office@grema3d.com |

|

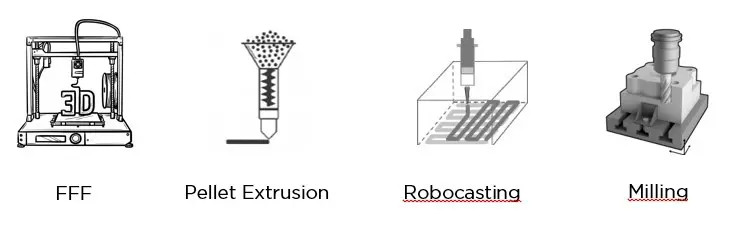

The M.A.T. has been designed as a versatile, accurate and robust 3D tool for research centers which want to develop in house new materials or new 3D technologies.

3DCeram Extruders:

- FFF head for working with ceramic and metal filament

- Pellet Head for working with ceramic and metal pellets

- Robocasting (one-component or two-component) for ceramics, metal and silicone

-3-axis CNC tool for green machining of printed parts before sintering

Fused Filament Fabrication (FFF)

The MAT’s FFF Head uses specially fabricated metal or ceramic filaments which are shaped into desired geometry using specially developed in-house water-cooled head. The printed “green” parts subsequently subjected to debinding (process of elimination of binder) followed by sintering (process of compacting the fine ceramic powder) to obtain a pure part of ceramic. The “green” parts can also be chemically treated in acetone -prior to heat treatment – to speed up the heat treatment process.

Direct Pellet Extrusion Printing

3DCeram has just recently introduced its new direct pellet extrusion head (on its MAT Machine for prototyping of technical ceramics and metals. The Pellet Head, as the name suggests, works directly with injection molding pellets or granulates. The 3D-Printing of pellets offers several advantages like material-cost saving, water debdinding, and recyclability.

Robocasting

Robocasting is a well-established process ceramicists use to extrude ceramic slurry though a nozzle. The process works with slurry or pastes instead of filament or pellets and requires a short and straightforward process to produce the 3d-printing material. In addition, binders like water can be used to prepare slurry such that debdinding and sintering can be carried out in a single furnace. The flexibility in terms of slurry preparation comes at the cost of reduced extrusion control and higher surface roughness. 3DCeram offers heads for single-component as well as two-component robocasting.

Green Machining

The MAT machines capability to host a CNC milling tool in addition to a pellet head for green machining improves surface finish of the parts – which can have a significant influence on the mechanical characteristics of the manufactured part. The added freedom of this green machining on the same machine eliminates the need for clamps and fixtures, and reduces the cost and time normally associated with hard machining of sintered parts. The green machining can be done after printing or can be done simultaneously with printing (printing 5 layers and machining, and then printing again..).